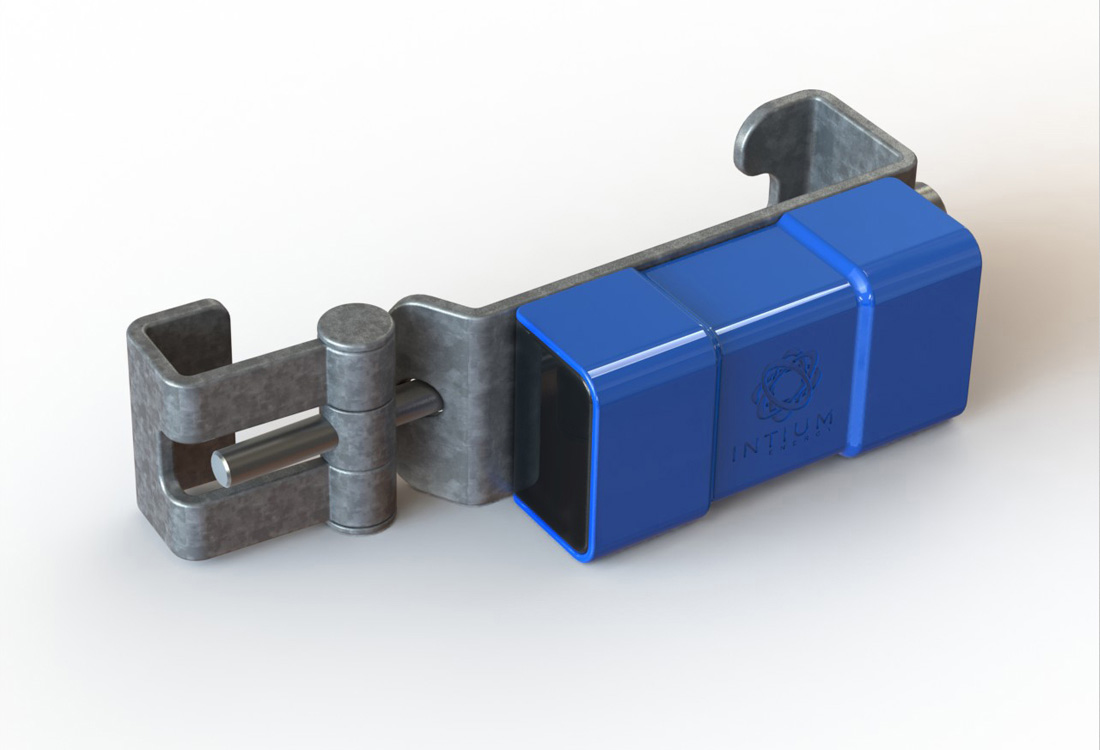

Intium Energy Casing

INTIUM ENERGY PROJECT BRIEF

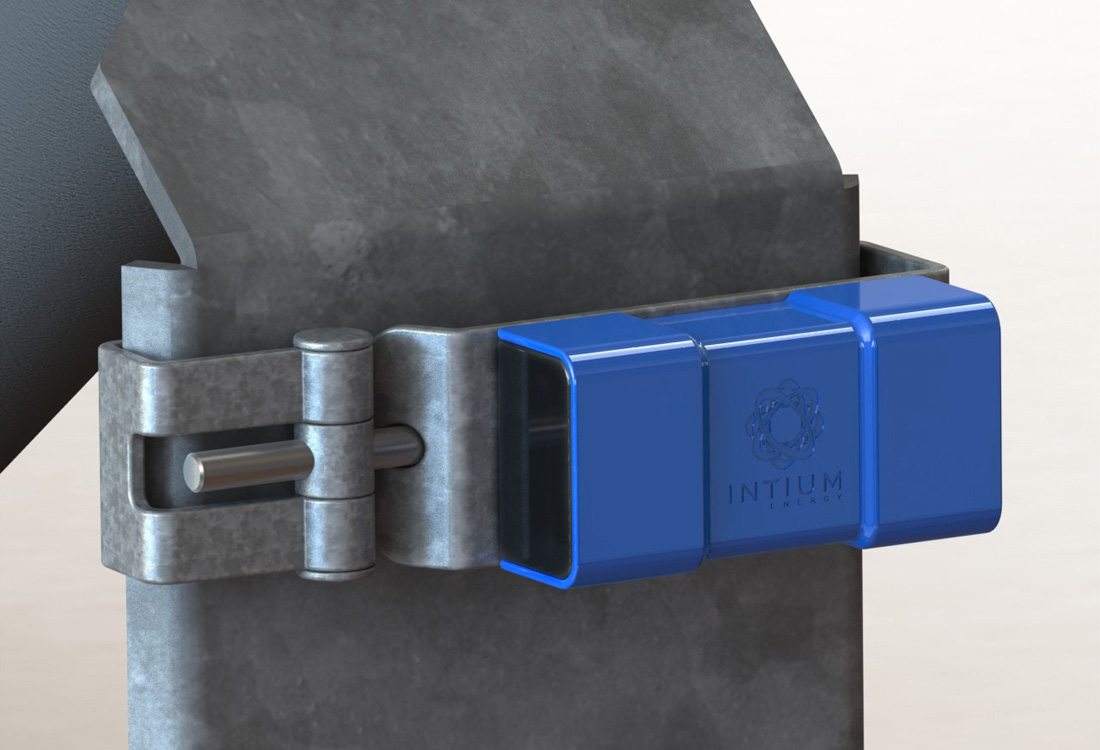

Conveyor belts used to transport mined resources are very common. The rollers used to mobilize the conveyor system usually consist of a bearing mechanism. These bearings have a life expectancy and eventually fail, which can result in costly downtime or even major losses in the event of catastrophic failure. The aim of the Intium Energy project is to create a bearing failure monitor to identify problems in the bearings earlier and respond faster, to minimise downtime and losses.

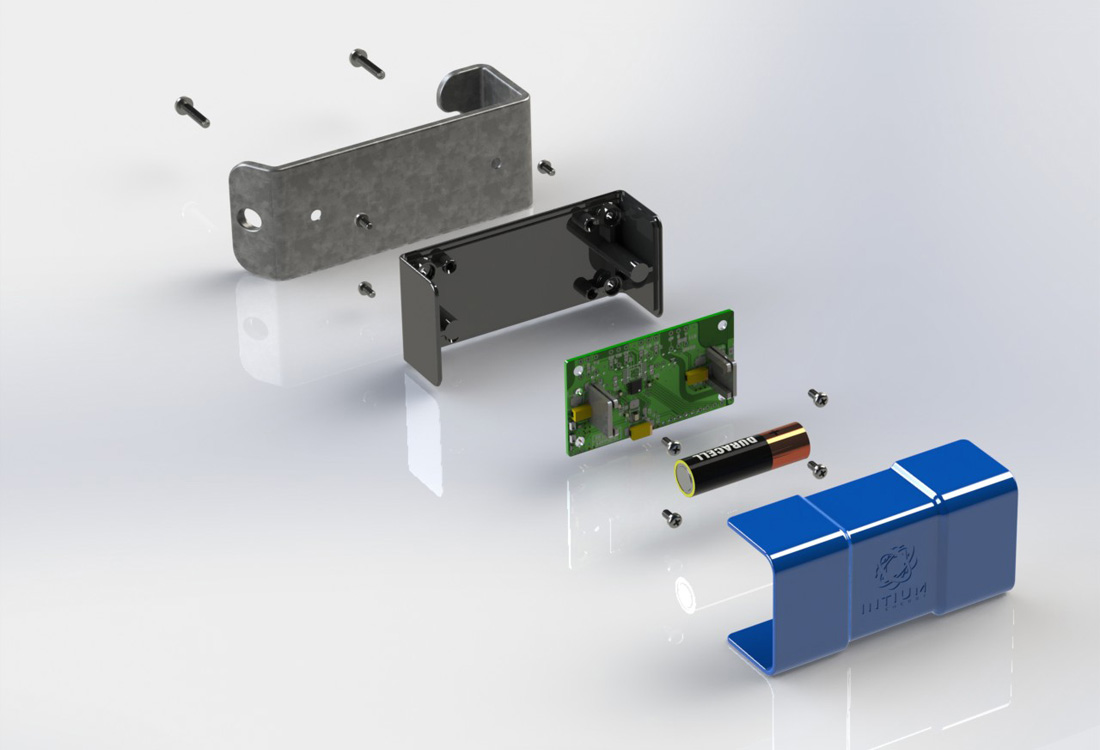

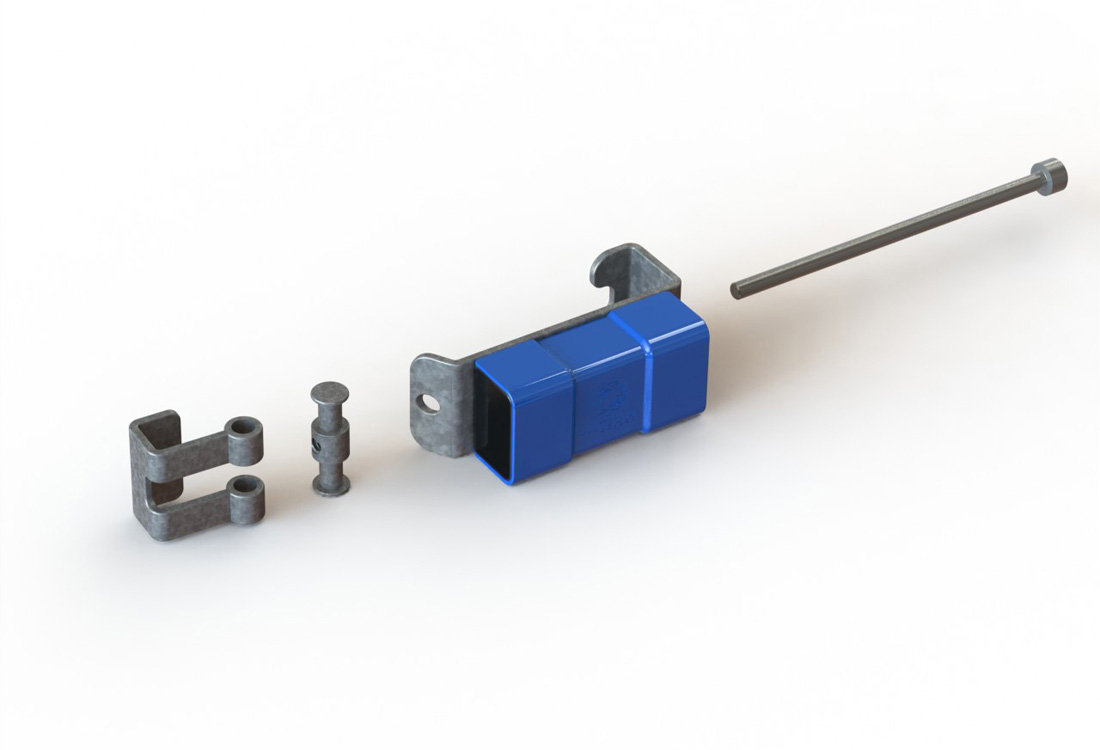

INTIUM DESIGN

The challenge of this project was to create an appropriate housing for the bearing monitor. Working with a technology company, Intium Energy, that services the mining and resources industry meant that the performance of the monitor housing was incredibly important. The design team had to focus on safety and reliability of the casing, and the result was a device that was durable and reliable in the face of very harsh industrial environment.